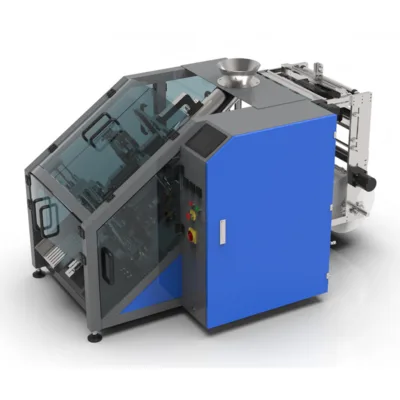

Overview

The collar-type vertical packaging machine is a highly efficient automated packaging equipment widely used in the food, chemical, pharmaceutical, hardware, and fastener industries. Its unique collar design improves the sealing and aesthetics of the packaging bag, ensuring long-term freshness and safety of the product. This equipment is suitable for packaging various types of materials, including granules, powders, liquids, and strips, and features high speed, high precision, and ease of operation. Through advanced control systems and automated processes, the collar-type vertical packaging machine not only improves production efficiency but also reduces labor costs, making it an indispensable packaging piece in modern production lines.

Features

- Industrial-grade construction with ergonomic design ensures long-term stable operation and easy maintenance.

- Touch screen paired with PLC control system, Formula storage and retrieval, production capacity statistics, human-machine interaction, easy to operate.

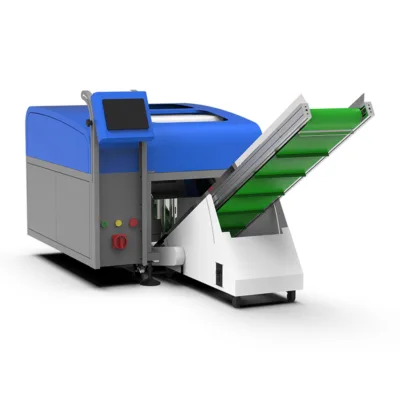

- Can automatically complete processes such as feeding, sorting, counting, bag making, loading, sealing, and finished product transportation, etc.

- Optoelectronic automatic tracking, with no action when there is no material, shutdown alarm, etc, Ensure that every step is precise and error free.

- Recipes and parameters can be stored and used for production with a single click, making it simple and fast.

- Reduce dependence and errors on workers, lower customer complaint rates, improve overall efficiency, and achieve true cost reduction and efficiency improvement.

- Modular design, Relevant equipment and functions can be added or removed according to demand, easy to expand and upgrade.

- Can interface with various front-end devices, such as counting systems, weighing systems, screening machines, visual counting machines, injection molding machines, production lines, etc

Video

Equipment Parameters

| Model | DXD-520 |

| Production speed | 10-100 bags/min |

| Packing size | W20-250mm, L30-380mm |

| Max film width | 520mm |

| Packing film material | OPP/CPP, PA/PE, PET/PE |

| Power | AC220-380V/50-60Hz/2.5kW |

| Air pressure | 0.6-0.8Mpa |

| Equipment weight | 300kg |

| Machine size | L1826mm, W1225mm, H1710mm |