Overview

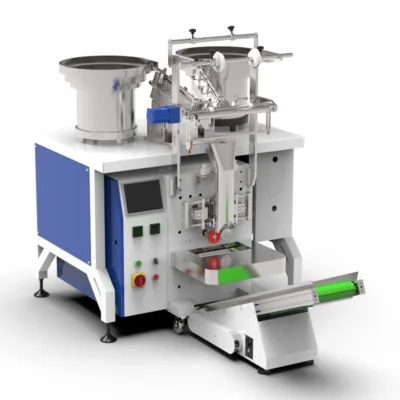

The screw counting and packaging machine is an intelligent device integrating automatic counting, sorting, and packaging, suitable for various specifications of screws, nails, and other fasteners. The machine employs advanced photoelectric sensing technology and a dual counting system with a positioning system to ensure accurate counting, and features high-speed operation and compatibility with multiple specifications. It is easy to operate, supports one-button start, and produces neat and attractive packaging. It significantly improves production efficiency and reduces labor costs, and is widely used in industries such as hardware, electronics, furniture, and automotive parts, making it an ideal choice for enterprises to achieve automated packaging.

Features

- Industrial-grade construction with ergonomic design ensures long-term stable operation and easy maintenance.

- Touch screen paired with PLC control system, human-machine interaction, easy to operate.

- Multiple packaging methods, including mixed packaging, individual packaging, and divided packaging.

- Can automatically complete processes such as feeding, sorting, counting, bag making, loading, sealing, and finished product transportation, etc.

- Optoelectronic automatic tracking, with no action when there is no material, shutdown alarm, etc, Ensure that every step is precise and error free.

- Advanced counting system, fast running speed, high accuracy, and strong anti-interference ability.

- Recipes and parameters can be stored and used for production with a single click, making it simple and fast.

- Reduce dependence and errors on workers, lower customer complaint rates, improve overall efficiency, and achieve true cost reduction and efficiency improvement.

- Modular design, Relevant equipment and functions can be added or removed according to demand, easy to expand and upgrade.

Video

Equipment Parameters

| Model | DXD-320T2 |

| Production speed | 10-100 bags/min |

| Packing size | W20-180mm, L30-220mm |

| Max film width | 380mm |

| Packing film material | OPP/CPP, PA/PE, PET/PE |

| Power | AC220-380V/50-60Hz/2.6kW |

| Air pressure | 0.6-0.8Mpa |

| Equipment weight | 350kg |

| Machine size | L1860mm, W1100mm, H1314mm |